Hospital supply chains are the backbone of clinical readiness, yet many systems still rely on outdated methods that create costly blind spots. Periodic audits, spreadsheets, and barcode scans create delays between consumption and recording. These gaps result in stockouts, unnecessary spend, and operational inefficiencies. Real-time inventory visibility has become the foundation of healthcare supply chain optimization, providing continuous data that eliminates guesswork, improves accuracy, and supports better patient outcomes.

The High Cost of Limited Inventory Visibility

According to Becker’s Hospital Review, inefficient inventory management costs U.S. hospitals more than $25 billion annually. Much of this loss comes from expired supplies and emergency orders triggered by outdated replenishment practices.

Without accurate, real‑time data, procurement teams often over‑order “just in case,” while clinicians waste valuable time hunting for critical items. Stockouts ripple through the organization forcing last‑minute substitutions, delaying care, and eroding staff confidence.

Hospitals adopting AI-powered stockout prevention are finding that continuous monitoring and predictive analytics can stop shortages before they happen.

Why Real-Time Inventory Tracking Matters

Real‑time visibility aligns supply levels with actual usage not with historical trends or static reorder points. Instead of waiting for an inventory audit or for staff to flag a shortage, systems update automatically as items are consumed.

In a busy surgical suite, for example, even one overlooked shortage can disrupt scheduled procedures. Hospitals implementing AI for healthcare inventory management are seeing measurable gains—automated systems track stock levels passively, sending alerts or triggering reorders before supplies run low.

This proactive model shifts inventory from a reactive task to a strategic advantage.

How AI Hospital Inventory Management Enables Real-Time Tracking

AI hospital inventory management platforms combine computer vision, IoT sensors, and predictive restocking software to provide continuous visibility across every storage area. Unlike barcode or RFID systems, AI-powered systems require no manual scanning, reducing labor while improving accuracy.

Legacy tools provide only partial solutions. AI‑powered real‑time insights integrate with ERP and supply chain software to deliver actionable data that enables procurement teams to move from reactive ordering to proactive replenishment.

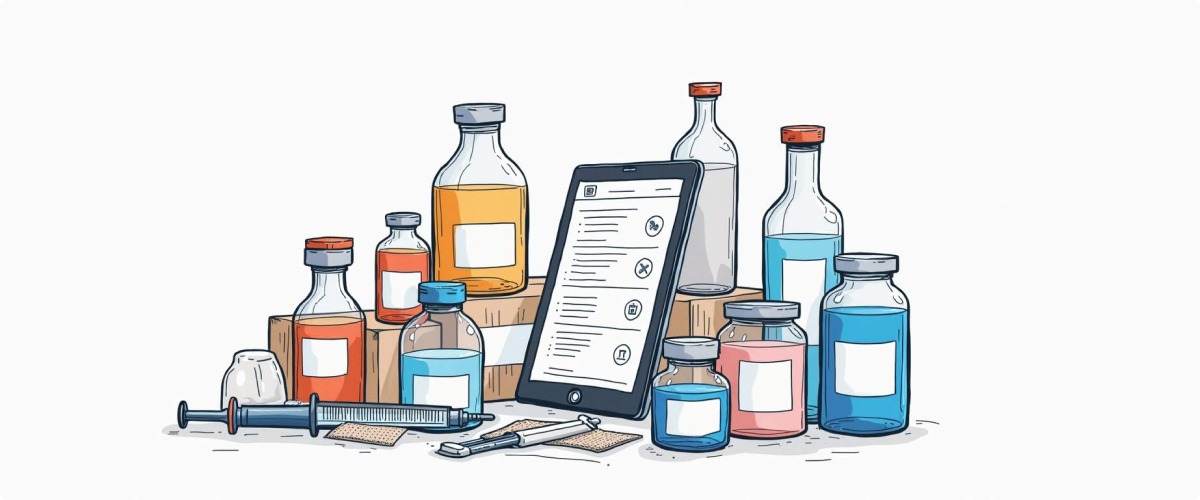

From Reactive to Predictive Restocking

Traditional min/max reorder levels can’t adapt to sudden changes in demand. Predictive restocking software uses a blend of real‑time consumption data and historical usage patterns to forecast needs days in advance.

If PPE usage spikes due to increased surgical volume, the AI inventory tracking system automatically adjusts reorder quantities, preventing shortages without overstocking. Hospitals using this approach have reported 25–30% improvements in forecasting accuracy and 10–15% reductions in supply costs.

Operational and Clinical Benefits

Hospitals adopting AI hospital inventory management report dramatic reductions in manual tasks. Staff time spent on counts and restocking has dropped by 65–75%, allowing clinical teams to focus more on patient care. Real-time visibility also reduces waste by ensuring inventory is only ordered when needed and stored in optimal quantities.

These operational gains translate directly into measurable financial returns. Clinicians spend less time tracking supplies, procurement teams make smarter purchasing decisions, and finance leaders gain a clearer view of spend.

The Financial Impact of Real-Time Inventory Visibility

The ROI is compelling. Hospitals aligning inventory levels with actual consumption are lowering costs by 10–15% while reducing waste and freeing resources for patient care initiatives.

Real‑time visibility also builds resilience allowing supply chains to adapt quickly to disruptions without costly overcorrections.

Laying the Groundwork for Automation

Real‑time visibility provides the foundation for predictive restocking and advanced automation. With continuous tracking, hospitals can implement touchless replenishment that eases staff workload and reduces errors. Over time, these systems shift inventory management from a reactive process to a proactive, resilient operation that adapts quickly to fluctuations in patient volume or supply chain conditions.

What to Consider When Adopting Real‑Time Visibility

The most effective solutions can scale to manage thousands of SKUs across multiple sites, maintain high‑quality data for accurate forecasting, and adapt to existing workflows without adding complexity. Ease of use is equally important—systems should be intuitive so staff adoption is seamless and training requirements are minimal.

Building a Future-Ready Supply Chain

Real‑time visibility is more than an operational improvement, it’s a strategic investment in supply chain resilience. By embracing AI‑driven visibility now, hospitals can position themselves for a future where inventory management is fully automated and aligned with both clinical and operational priorities.

Ready to see how real‑time inventory visibility can cut costs, stop stockouts, and strengthen your hospital supply chain? Schedule a consultation to explore how our healthcare supply chain optimization solution delivers measurable ROI.